Use the Isel lubricant finder to make sure you are buying the correct product that fits your needs. Match your current lubricant to an Isel replacement or search for your new lubricant based on how it will need to perform.

Resources

eBook Downloads

Selecting the Right Lubricant for Your Refrigeration System

Get a lubrication comparison chart to help you select the right lubricant for your refrigeration system.

The Benefits of Oil Analysis

Learn how accurate and safe oil sampling prevents equipment downtime and enhances your company's bottom line.

Rotary Screw Compressors: Lubrication Comparison Chart

Make the selection process easy and access our comparison chart of lubricants for rotary screw compressors.

Lubrication Glossary of Terms

Access our lubrication glossary of terms so you can be prepared for any production issues that may arise in your system.

Blogs

How to Use the Isel Lubricant Finder

The Isel Lubricant Finder offers a quick and easy way to identify Isel lubricants that are ideal replacements for the formulations you use.

The Importance of Lubrication in Rotary Screw Compressors

Lubricants are designed to prevent rust and corrosion, resist thermal and oxidative degradation and impede the formation of contaminants.

What's the (Pour) Point?

If your application involves refrigeration or operates in a cold climate, the pour point of your lubricant is most likely a critical property.

Technology Articles

Avoid Oil Sampling Pitfalls

When collecting oil samples for routine oil analysis, where and how should you do it?

Water Hazard: Protect Lubricants and Equipment from Water Contamination

Removing excess water from a lubricant in a timely manner can help avoid serious damage to the fluid and components.

Avoid These Lubrication Mistakes

The best way to determine the correct frequency of oil changes is to eliminate the guesswork and turn to regular oil analysis.

Q&A Articles

What is GHS and How Does Isel Comply?

OSHA's updated GHS rules provide a globally standardized approach to chemical safety.

How Can Tiny Dust Particles in a Lubricant Harm Machinery?

As they scratch and scrape away at metal surfaces, dust particles generate metal-wear particles that further contaminate the lubricant.

What Factors Affect the Shelf Life of a Lubricant in Storage?

Extreme heat or cold, fluctuating temperatures, moisture/humidity, dust and dirt can shorten the life span of stored lubricants.

Company News

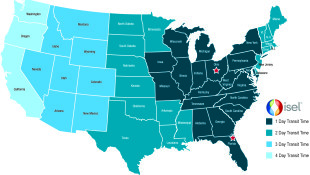

Isel's New Ohio Facility Will Expand 1-Day Shipping Turnaround Capabilities

Isel's new facility in Columbus, Ohio, will allow us to provide unmatched order turnaround time and shipping.

Isel Takes the Lead on Green Initiatives

In our continuous efforts to better support our clients and the communities they serve, Isel is proud to announce the launch of our Sustainable Packaging Recovery Program.

Mark Your September Calendars: Come See Isel at Trade Shows

Isel will be exhibiting at the RETA National Conference 2015 and the FPSA 2015 Process Expo.

Prolong Equipment Life: Keep Lubricant Oxidation At Bay

It’s a simple fact of lubricant life: Lubricants do not last forever. Even under the best conditions, a lubricant will eventually degrade over time due to a process known as oxidation — the chemical reaction...

Read More

Category:

Technology

Technology

Q: Is NLGI Grade Essentially The Same As Viscosity?

A: No. NLGI grade (named for the National Lubricating Grease Institute that developed the grading system), is primarily a function of the thickener used in the grease formulation. Meanwhile, the base oil(s) used in grease...

An Introduction To Industrial Lubricant Additives

The world of lubrication is one of diversity: Each machine, application and set of operating conditions demands a particular combination of lubricant properties and functions. These demands create the need for a broad spectrum of...

Read More

Category:

Technology

Technology

- SORT BY:

- News

- Q&A

- Technology