Ammonia & CO₂ Lubricants

Ammonia & CO₂ Lubricants

Better, More Efficient Ammonia Systems

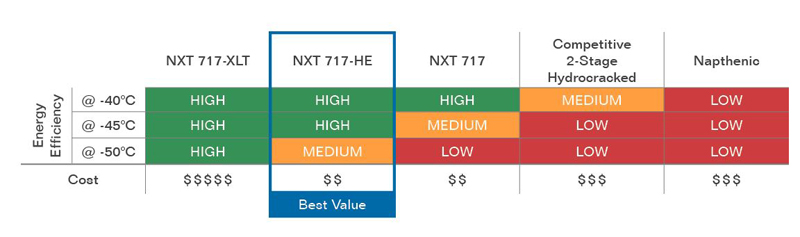

The NXT 717 family represents the next generation of 2-stage hydrocracked lubricants. Every NXT ammonia lubricant takes into consideration the operating conditions of the facility, the refrigerant-lubricant interaction in the system, the estimated energy savings the lubricant can provide and numerous other factors.

Increased Low-Temperature Fluidity & Improved Energy Savings

NXT ammonia compressor lubricants remain mobile at extreme cold temperatures, preventing clogging and build-up inside narrow evaporator passages.

Facilities running the NXT 717 family of lubricants have saved thousands of dollars annually in energy savings when switching from leading competitive lubricants.

The combination of lower solubility with ammonia, reduced carryover, and better pumpability results in significantly greater evaporator efficiency.

Reduced Oil Carryover to Evaporators, Extended Fluid Life & Protection

Extremely low volatility and solubility in ammonia systems ensures that NXT 717 reduces oil carryover. This causes the evaporator to operate more efficiently and at a higher capacity.

The enhanced oxidative stability of NXT 717 helps to extend oil life. The advanced additive package controls and prevents corrosion of system components.

Customers running NXT 717 have seen upwards of 72% reduction in annual oil use.1

1: Large food processing facility using 24 MYCOM screw compressors switching to NXT 717

1: Large food processing facility using 24 MYCOM screw compressors switching to NXT 717

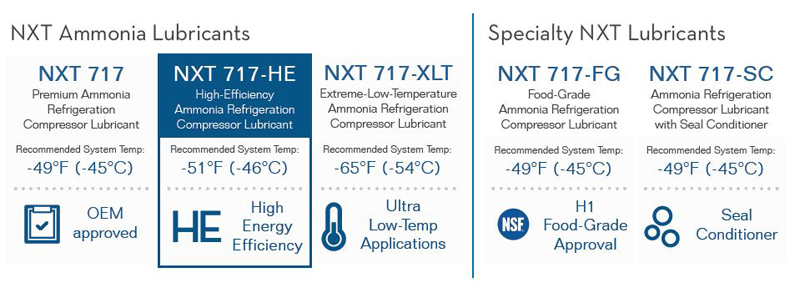

Enhanced low-temperature pumpability and protection with reduced oil carryover

A high-efficiency ammonia refrigeration compressor fluid specifically designed to lower energy consumption in compressors.

Conditions/restores hardened seals and maintains pumpability in low temperatures

A food-grade lubricant offering long-lasting protection and varnish control

Superior cold-temperature pumpability, lubrication and emulsification control

Reliable lubrication and pumpability in very cold temperatures

Lubricates and reduces oil carryover in high-pressure ammonia heat pumps